Steel Beam Basics Guide: Uses, Types, & Reading Sizes Explained

January 29, 2025 | Categorized in: Types

Steel beams can seem simple when you glance at them, but there is a huge mix of types, variations, measurements, and more that are tailored to different applications and purposes.

We’ve created guides like this for other structural steel shapes as well, such as rebar, piping, angles, plates, and grating. Whether you’re just looking to learn or you’re planning on buying some, we’re here to break it down so you can feel confident talking about and buying the right beams for your needs.

What is a Steel Beam?

A steel beam is a structural shape that’s widely used across many industries and projects. Made from high-strength steel, they are long, horizontal, or sloping structural elements designed to bear loads and provide support for construction projects. Steel beams come in various shapes and sizes to fit specific needs. One example is I-beams, which are called such as their profile is shaped like a capital I (or an H if you turn it on its side).

Steel beams are very strong and they can distribute loads and resist bending, ensuring stability and durability in structures. But at the same time, that can make them very heavy, which is why they can also be cut in half along their length to create tee beams. These steel beam shapes are referred to as T-beams to match their profile.

Structural Steel Beam Applications

At their most basic, steel beams are for supporting heavy loads due to their immense strength. More specifically, they’re often used in construction and civil engineering structures such as supports for bridges or the primary frames of buildings. Here are a few more examples of the most common uses for steel beams:

- Commercial and residential buildings: Providing support for floors, ceilings, and roofs.

- Bridges and overpasses: Offering structural integrity and load-bearing capabilities.

- Skyscrapers: Acting as primary vertical and horizontal support beams.

- Industrial warehouses and factories: Used in building frames and overhead support systems.

- Parking garages: Withstanding heavy loads from vehicles.

- Retail and hospitality spaces: Supporting large open areas without the need for intermediate columns.

- Stadiums and arenas: Ensuring structural stability for large, open spaces with minimal support.

As we’ll discuss, they have excellent strength and weight-bearing characteristics for things like supporting floors and roofs, which makes them ideal choices for most construction and infrastructure projects.

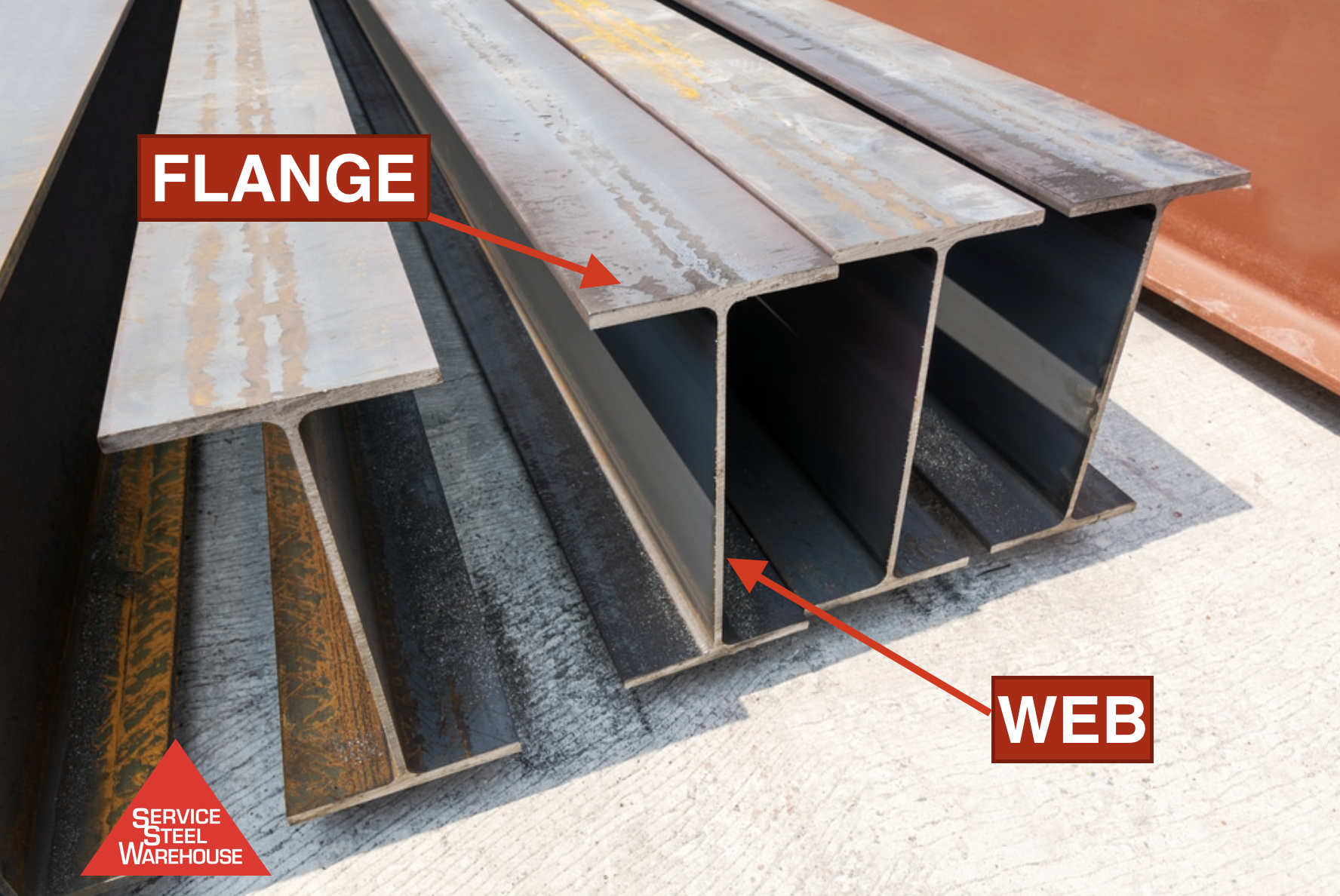

Parts of a Steel Beam

While a beam’s strength partially comes from the strength of steel, is also a result of their shape. A steel beam is made up of two basic parts, both of which can vary in dimensions for different applications.

|

Part |

Description |

Purpose |

|

Flange |

The top and bottom horizontal parts of the beam, often wide. |

Provides strength and resistance to bending. |

|

Web |

The vertical section connecting the flanges. |

Transfers shear forces and provides vertical support. |

Flanges: When looking at the profile of a steel beam, it looks like an I. The (typically shorter) horizontal pieces on the top and bottom are called the flanges. Their edges can be parallel or tapered depending on the type of beam. The purpose of flanges is to resist the bending moment or forces experienced by the beam.

Web: The web of a beam is the (typically longer) vertical piece that connects the two flanges in the center. The radius of the corner where each flange meets the web can also vary depending on the beam. The purpose of the web is that it resists shear forces that could cause collapses or breaking.

Together, web and flanges work to provide great strength for shearing and bending, which is why beams are so common in bridges and building frames. However, a beam’s shape has relatively low resistance to torsional (or twisting) forces.

Beyond the webs and flanges, there are other key components of steel beams that influence their strength and use:

|

Part |

Description |

Function |

|

Depth |

The overall height of the beam (from top flange to bottom flange). |

Determines load capacity and beam strength. |

|

Thickness |

The thickness of the web and flanges. |

Affects the beam’s ability to handle specific loads. |

|

Length |

The horizontal span of the beam. |

Determines the beam’s span between supports. |

|

Welds |

Connections at various points to hold the beam together. |

Ensures the integrity of the beam’s structure. |

Types of Steel Beams

Within this category, there are a couple of different steel beam shapes (or letters) you’ll likely run across. Though we won’t cover them all in great detail with this guide, you’ll find the most common types of steel beams are:

- H Piles

- I-Beams (or Standard Beams)

- W-Beams (or Wide-Flange Beams)

- T-Beams

H-Piles vs. I-Beams

Relatively similar in height-to-width ratio, I-beams and H piles are both shaped like their letter designation. The primary differentiator between these two product types is that while H piles flanges are parallel and flat, I-beam flanges are tapered and get thinner further from the web.

Click Here to See Our Inventory of Steel Beams

W-Beams vs. I-Beams

Now when we compare I-beams to another beam variation, W-beams (also known as wide flange beams), we see a more obvious shift simply from the name. As you might have guessed, W-beams have flanges that are wider than your standard I-beam, and this is the main difference between the two. Because of this, steel W-beams can often hold more weight and resist higher forces than I or H piles.

Understanding Steel Beam Sizing

When reading beam sizes, they often are written like “W 27 x 178#” or “S 24 x 121#”. This might seem confusing if you’ve never tried to purchase or work with steel beams before, but it’s very straightforward once you understand the format:

- The first letter indicates the general shape or type of beam, in this case, W means it’s a W-(or wide flange) beam whereas S is for an S-(or Standard American) beam.

- The number that follows the letter is called the section number and is the “height” of the I.

- The second number is the pounds per lineal foot, or how much each foot of the beam weighs.

- Sometimes, there will be a third number that represents the length of the beam (in feet).

W 27 x 178#

Using these examples, the wide flange beam is 27 inches tall and weighs 178 pounds per foot. If that beam is 40 feet long, we can multiply the weight per foot by the length to estimate that the total weight would be 7,120 pounds.

S 24 x 121#

Following the example above, the S-beam is 24 inches tall and weighs 121 pounds per foot, leading to a 4,840 total weight if the beam is 40 feet long.

While these are the major pieces of information for reading a steel beam size, the flanges and web also have individual dimensions and characteristics that are often displayed in full steel beam sizing charts. For more information, visit our I-beam or W-beam pages to view their sizing charts.

Here for All Your Steel Beam Needs

Steel beams are essential for any construction project, providing the strength and stability necessary to support various structures, from bridges to skyscrapers. Understanding the different types of steel beams, their parts, and how to properly size and measure them is crucial for any project’s success.

Ready to get started on your next project? Give us a call, send us an email, or fill out this short form for a custom free quote. Our team is ready to discuss how our structural steel beams can meet your project’s needs. Whether you’re building a residential property or working on a massive industrial project, we’ve got you covered!