About Service Steel Warehouse

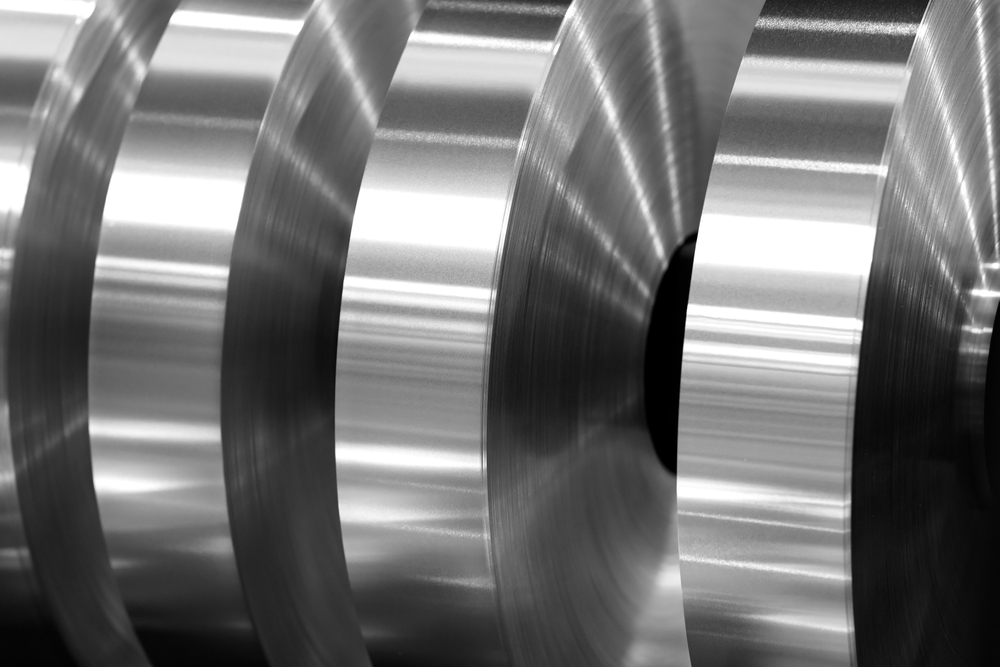

Founded in 1965 in Houston, Texas, Service Steel Warehouse is a nationwide full-service supplier distributing structural steel, providing slitting services and more. Not only do we offer a full stack of steel services to customize your order to exactly meet your needs, but we also stock a wide range of carbon steel products.

- One-Stop Shop: We stock a comprehensive selection of carbon steel, plus services like impact testing and flame cutting to meet your specific needs.

- Fast & Reliable: Our extensive steel inventory across multiple warehouses ensures most products are available for next-day shipping.

- Convenience: Benefit from our just-in-time delivery for a streamlined supply chain.

With locations throughout the Gulf Coast and Midwest, our warehouses can get you the steel merchants and steel slitting services you need quickly and competitively priced.

Fill out this form or call our team directly to get a fast and free quote for your next project!