Steel Plate Basics: How They’re Made and How They’re Used

April 11, 2025 | Categorized in: Types

In some of our other resources, we’ve discussed the basics of other structural shapes such as beams, pipes, angles, coils, and rebar. While steel plates are about as simple as steel products come, there’s still plenty to discuss in regards to what defines them, what they’re used for, as well as their sizing charts and conventions.

What is plate steel?

Steel plates are generally rectangular, flat steel products that are used in a variety of structural applications. They are often cut or transformed into different steel shapes to fit a number of different applications. The most common alloys used for steel plates are A36, A572 (Grade 50), and A786. All of which are available in our inventory.

What’s the difference between steel plate & sheet metal?

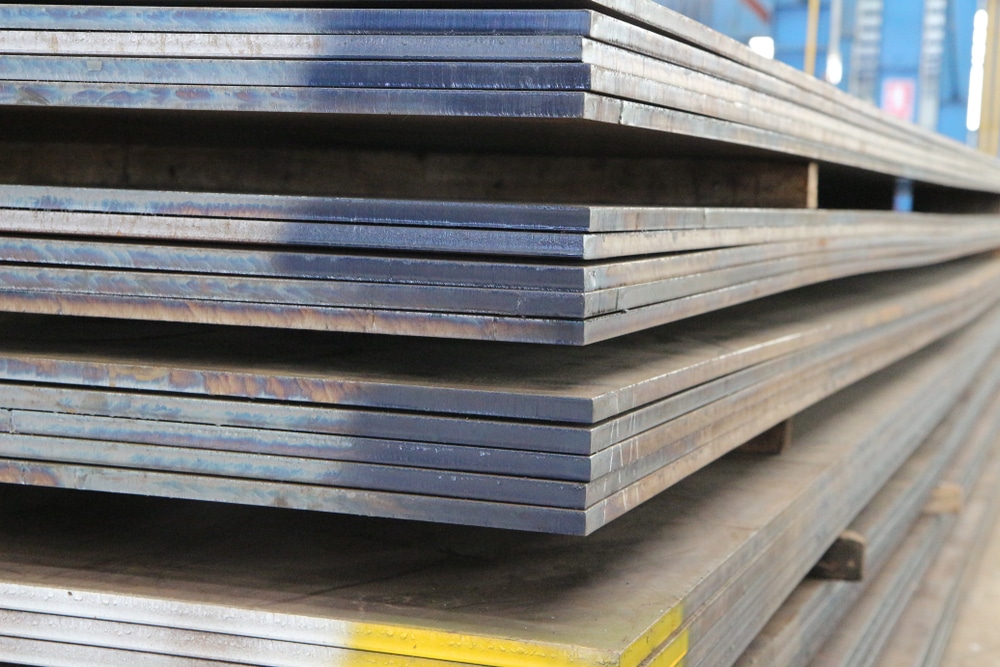

It’s not uncommon to think of steel plates and steel sheets as closely related. The boundary that separates the two is primarily the thickness, where the product is considered a “plate” if its thickness is greater than ¼” (6mm). If the thickness of the steel is less than that, it’s considered a steel sheet. Another way you can tell is that steel plates are stored by stacking them, while sheet steel is coiled.

Understanding steel plate fabrication

The most common way that steel plates are manufactured is through hot rolling, where steel slabs are heated until they are more malleable. The steel is then run through a series of rollers that flatten and thin them out to the desired thickness. When making these plates, it’s common to start with multiple layers of steel that are slowly compressed into one plate. The plate is then cut to the required dimensions for a given project.

What are steel plates used for?

Because of their simple nature, steel plates are used for a wide range of applications in a variety of industries. Some common uses for plate steel include:

-

- Bridge and building construction: Metal plates are used primarily to strengthen the foundations of large structures such as bridges and warehouses, as well as for anchoring steel beams in these situations.

- Military shielding: Many military vehicles and buildings use steel plates for protection against gunfire and other dangers.

- Ship construction: Due to their strength and ease of welding, steel plates are also common in large ships, and are one of the most common materials used in the building of these boats.

- Road plates: While construction is being done on streets, steel plates are commonly used as a temporary surface for traffic to pass over, and can cover potholes, trenches, excavations, and other damage to the normal road surface.

- Shipping containers: According to the World Steel Organization, steel ships transport 90% of the world’s cargo across the globe, much of which is fabricated from steel plates to preserve the life of the containers.

There are many more uses for steel plates, but these are some of the top situations where this critical steel shape is most often used.

Steel plates grades

Steel plates are categorized into different grades based on their properties and composition, which includes their strength, durability, and usage. Some of the most common types of steel plate grades include:

- Carbon steel is the most frequently used and comes in varying levels of strength and ductility, which is dependent on the level of carbon added. These types include low, medium, and high carbon steel.

- Alloy steel is a type of steel grade that has additional alloying elements beyond carbon that are added to enhance specific properties.

- Stainless steel contains at least 10.5% of chromium which forms a protective layer on the surface for additional corrosion resistance. The biggest drawbacks to this grade for steel plates is the high cost and maintenance needed to maintain its appearance.

- Tool steel is known for its hardness, resistance to wear, and ability to maintain its shape under high temperatures, making this grade of steel plate popular for use in hand tools and machine dies.

Steel plate thickness charts

A steel plate thickness chart is used to list out the dimensions of steel plates in relation to their thickness. These charts provide help and direction in choosing the most appropriate plate thickness for the project. Some of the influencing factors include weight limitations, strength requirements, bending forces, and of course, cost.

Unlike steel sheets, which usually use gauge numbers to measure thickness, steel plates almost always use inches. This makes it easy to not only understand plate sizing charts, but also to visualize the size of the plates. Besides metrics such as thickness, width, and length, weight is also a common consideration with steel plates. The weight per square foot will obviously change with the thickness, but also with the steel grade and finishing services (such as painting, galvanizing, and tread pattern).

Get strong steel plates for your project today

No matter what type, size, or specification of steel plates you need, Service Steel can supply it. Even better, our experts can help you decide what the best choice is for your project so you don’t need to feel pressured to be an expert in steel plates and standard sizing.

We’ve built a reputation on premium quality and exceptional service. That means we can always ensure you get plate steel that you can trust and that meets ASTM standards. Our massive ready-to-ship inventory of high-quality steel is ready for your order, so request a quote or give us a call today!