There are many corrosive elements and chemicals throughout the oil and gas processing operation, including sulfur, chlorides, and acids. This means that very few materials can withstand these environments, and even fewer when temperature and pressure are added to the mix. This is where steel comes in, allowing the oil and gas industry to collect, transport, refine, and store without worrying about material failure.

From oil country tubular goods (OCTG) to platforms and jackets to storage tanks and pressure vessels, steel can handle the job and Service Steel Warehouse can supply the steel.

Why Choose Service Steel Warehouse?

Our competitive edge is in our name: Service. Since our humble beginnings in 1965, we have taken pride in the accuracy, speed and quality of service we offer you.

Massive Stock

Our huge inventory means you don’t have to visit several suppliers to find what you need for different uses and parts of the processes.

Ready-to-Ship Inventory

Our supply of steel products is also ready to ship the following day and allows you to get to work even faster.

Premium Quality

Our steel is high-quality and available in different specifications for a variety of applications in the oil and gas industry, from flowlines and structural components to storage.

Environmentally-Friendly

Steel is not only 100% recyclable, but also has relatively low consumption of energy in the manufacturing process.

FIND OUT MORE

Call Us Now: 800-675-9929

Steel Applications in the Oil & Gas Industry

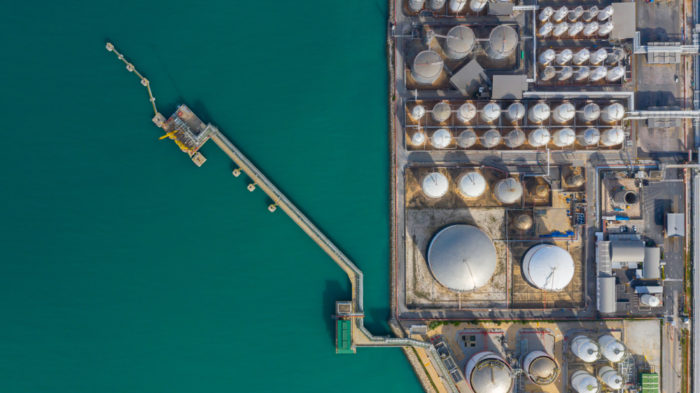

Oil Storage Tanks

Oil Country Tubular Goods

Structural Components

Flowlines

Oil & Gas Steel FAQs

Which specialized steel grades does Service Steel Warehouse stock for oil and gas infrastructure?

We supply steel products for the oil and gas industry in grades like ASTM A36, A572-50, A1011, and more. For detailed grade matching (e.g. oil-country tubular goods or high-strength alloys), contact our team for assistance in choosing the right product for your application.

What corrosion-resistant steel products and treatments does Service Steel Warehouse offer for chloride-rich or harsh environments?

We stock galvanized steel products, particularly for tanks (like oil storage) and outdoor infrastructure. These provide decades of rust protection for critical components under harsh conditions.

Does Service Steel Warehouse maintain inventory for upstream installations or refinery platforms?

Yes. We keep a massive ready-to-ship inventory on hand that supports fast deployment to oil and gas projects, including upstream installations and refinery platforms. Our next-day shipping further enables rapid mobilization and early project starts.

Can Service Steel Warehouse pre-fabricate module kits for faster assembly of platforms or skids?

Yes. Our comprehensive value-added services (from flame cutting, bending, sawing, to impact testing and more) support the creation of pre-fabricated module kits tailored for platform or skid assembly.

Are Service Steel Warehouse’s steel products compatible with welding and assembly in the field?

Yes. Our structural steel grades like A36, A572, and A706 are well-suited for field welding and assembly. Our in-house fabrication capabilities ensure that your components are prepped to meet site requirements, which eases on-site workflows.

How does Service Steel Warehouse support rapid procurement cycles during emergency maintenance windows?

Service is at the core of our competitive advantages. Our large inventory and ready-to-ship model allow us to respond quickly to turnaround or emergency maintenance needs, ensuring that critical materials are available and dispatched promptly.

Can I stage deliveries from Service Steel Warehouse to align with multi-phase installations?

Yes. Using our unmatched logistic capabilities and segmented distribution, we’re well-equipped to stage deliveries — first supplying raw materials to pipeyards, then delivering module kits or fabricated segments in alignment with phased installation schedules.