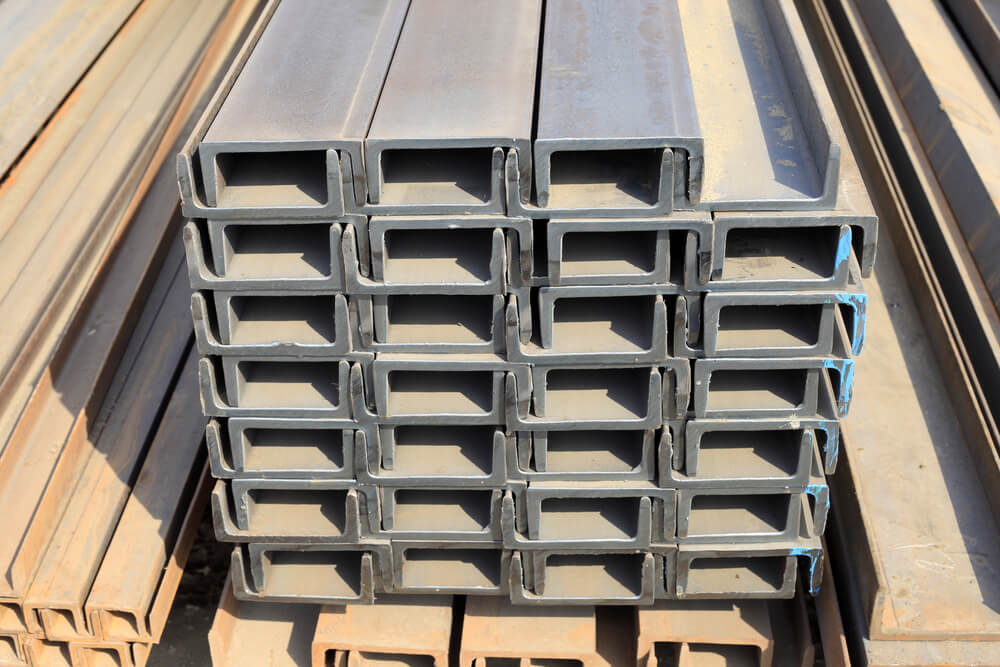

Service Steel Warehouse: Your MC Channel Supplier

Founded in 1965 in Houston, Texas, Service Steel Warehouse is a nationwide full-service steel channel supplier distributing and providing multiple steel services. Not only do we stock a wide range of structural steel for sale, we also offer a full stack of steel services to customize your order to exactly meet your needs. Services such as:

- Galvanizing

- Impact Testing

- Production Sawing

- Bending & Cambering

- Flame Cutting

- Sheet & Coil Slitting

- Tee Splitting

Since our humble beginnings, we have taken pride in the accuracy, speed, and quality of service we offer you. If you’re looking for a dependable steel supplier, Service Steel Warehouse is the best option available. Thanks to multiple offices across the South and Midwest, we have one of the largest inventories with a high volume of products available for next-day shipping as well as a convenient delivery program!

To request a free quote from our team of structural steel suppliers, give us a call or request a quote today.

Houston Shipments Instantly Available. Click Here to Learn More.

|

|

|

|