What is Reshoring? The Emerging Trend Bringing Manufacturing Back to the U.S.

February 29, 2024 | Categorized in: News

Amid the ever-evolving landscape of international trade, the practice of reshoring has seen an emergence as a way for industries to regain their autonomy, boost domestic economies, and better ensure their long-term sustainability. Within the steel industry especially, we’ve seen reshoring as a critical strategy that can reshape the dynamics of production and supply chains while fostering a resurgence of American manufacturing.

In this article, we’ll dive into reshoring, its transformative potential, and its profound implications for businesses seeking to thrive in an increasingly competitive marketplace. Learn the advantages of reshoring processes back to the U.S. and how it not only benefits businesses, but also local communities, and the broader economic landscape.

What is reshoring?

In short, the definition of reshoring refers to the practice of bringing manufacturing or production processes back to the “home” country from overseas locations. In other words, reshoring is the opposite of offshoring, where businesses move their domestic manufacturing to countries with lower labor costs or other benefits.

Though it is defined simply, reshoring can be a complex process that requires careful planning, strategic decision-making, and effective execution. While it presents incredible opportunities for cost savings and improved quality control, reshoring also entails its unique risks and challenges that companies must navigate.

Still, particularly in the U.S., reshoring has gained attention in recent years due to beneficial factors such as:

- Rising labor costs in some offshore locations

- Concerns about product quality control

- Supply chain disruptions

- A desire to support domestic economies and job growth

Advocates supporting the reshoring efforts

There are two main organizations dedicated to educating businesses and lawmakers about the benefits of reshoring. Both of these groups are great places to start if you are interested in learning more about reshoring processes for your business:

- The Reshoring Institute is a non-profit organization that provides resources, guidance, and consulting services to help companies assess the feasibility of reshoring, navigate the reshoring process, and optimize their domestic manufacturing strategies.

- The Reshoring Initiative focuses on reshoring as a means to strengthen the U.S. economy and create jobs, in addition to tracking reshoring trends, quantifying the impact of reshoring on job creation, and advocating for policies that support domestic manufacturing and reshoring efforts.

Benefits of reshoring

There are several reasons why American companies are choosing to bring back their overseas manufacturing and production processes. Some parts of reshoring benefit the company’s bottom line, while others can end up benefiting the U.S. economy as a whole! Here are the biggest advantages of reshoring:

1. Reduces costs across the supply chain

By relocating and reshoring operations closer to home, companies can mitigate various expenses associated with offshore production. Offshore manufacturing may initially appear cost-effective, but factors such as transportation expenses, tariffs, and currency changes can quickly diminish these “savings”.

With reshoring, companies can regain control over these factors, resulting in an overall reduction of expenses. This leads to enhanced profitability and competitiveness in their market, ensuring long-term sustainability and growth.

2. Creates jobs in the local economy

Reshoring manufacturing operations leads to job creation within the communities where operations are established. By moving these production facilities closer to their backyard, so to speak, companies contribute directly to the economic growth and prosperity of the areas where they are operating. Even through the hiring of local workers, companies can foster employment opportunities that support families and strengthen ties with the community.

According to data, over the first half of 2023, reshoring and jobs announced exceeded 2022’s record rate of around 340,000 jobs announced per year. These newly created jobs not only provide livelihoods for individuals but also contribute to the overall, long-term development of a skilled workforce. As local communities thrive with increased employment opportunities, businesses also benefit from a loyal and committed workforce, driving innovation and productivity within the company.

3. Streamlines quality control

Maintaining quality standards can be challenging when production is located far from the company’s headquarters. That’s how reshoring helps companies to ensure better quality control and consistency. When you have production facilities closer to where the products are designed and managed, you will also have better oversight and management of the manufacturing process, resulting in higher quality.

Additionally, reshoring manufacturing processes enables businesses to enact stricter quality control measures, leading to products that meet or exceed expectations. By bringing production closer to home, companies can closely monitor each stage of the manufacturing process, identifying and addressing any issues promptly. This focus on quality not only enhances product reliability but also boosts customer satisfaction and brand reputation.

4. Increases supply chain resilience

The COVID-19 pandemic highlighted vulnerabilities in global supply chains, emphasizing the importance of resilience and flexibility for all. This could be one of the biggest factors in why reshoring back to the U.S. has become a growing trend in the steel industry and beyond. By bringing production and manufacturing closer to home, organizations can reduce their reliance on international suppliers.

Additionally, reshoring can also aid in minimizing the impact of external disruptions such as natural disasters, geopolitical tensions, or trade disputes. This increase in supply chain resilience ensures continuity and minimizes disruptions, safeguarding business continuity and customer satisfaction.

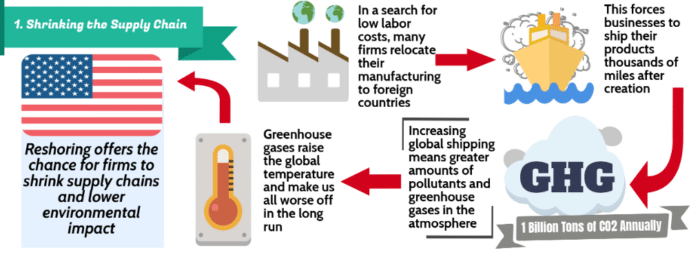

5. Minimizes environmental impact

One of the advantages of reshoring that has the widest impact is its contributions to helping organizations minimize their environmental impact. Producing goods closer to home means reducing the carbon footprint and emissions associated with long-distance transportation. According to the Reshoring Initiative, bringing back domestic manufacturing empowers companies to adhere to ethical environmental regulations and implement sustainable practices more effectively.

Credit: Reshoring Institute (Source)

By minimizing environmental impact, these organizations demonstrate their commitment to corporate environmental responsibility. This proactive approach not only benefits the planet but also enhances its own brand reputation and perception. As consumers increasingly prioritize sustainability, companies that embrace environmentally (and socially) friendly practices at every step of the supply chain gain a competitive advantage in the market.

Reshoring trends and how it impacts the steel industry

At Service Steel, we know from experience how offshoring and outsourcing can hurt American businesses, communities, and economies. Around two decades ago, many U.S. manufacturers began outsourcing their steel production overseas to cheap sources of labor such as China. The result? Less business for U.S. suppliers, plus lower quality and reliability for Americans.

Perhaps this is why we are seeing a shift in trends and a resurgence of bringing steel manufacturing back to the States. For example, Caterpillar Inc., one of the world’s leading manufacturers of construction equipment was one of the leaders in this recent trend in reshoring. A few years ago they brought back 1,900 jobs from overseas, moving their Japanese construction equipment production to Georgia and Texas.

As further proof, 96% of CEOs surveyed for the Kearney Reshoring Index in 2023, are considering, have started already, or have already reshored their business operations. This is a massive increase from 78% the previous year.

Simplify your steel purchasing process

As you can see, the benefits of reshoring (especially for the steel industry) extend far beyond individual businesses — instead, they can resonate throughout the American economy. By embracing reshoring, U.S. companies like us here at Service Steel, are contributing to job creation, economic growth, and supply chain resilience within the nation. Additionally, American-made steel products offer unparalleled quality, reliability, and adherence to stringent manufacturing, safety, as well as ASTM standards.

At Service Steel, we take pride in delivering top-notch steel products and services that meet the diverse needs of our clients across various industries. If you’re ready to experience the advantages of American-made steel for your next project, reach out or give us a call today for a custom quote to see how we can bring your steel project to life.